The total length of a plateau railway, which started construction in November 2020, is 1011km. The environment along the line is harsh, and the bridge tunnel ratio is as high as 95.8%. The construction period is as long as 10 years. A certain plateau tunnel has a total length of 42.3km and is designed as a double track separated single track railway tunnel with a maximum burial depth of 1506m. The project has the following characteristics: "One length": This tunnel is the longest tunnel in China's railway; "Two Duo": There are many natural disasters along the line and many unfavorable geological conditions in tunnels; "Four Difficulties": Difficulty in ventilation and dust reduction during long-distance excavation construction, difficulty in accurately predicting and protecting against high ground stress and rock bursts, difficulty in temperature reduction and prevention during long-distance excavation of high ground temperature tunnels, and difficulty in organizing construction with multiple working faces inside the tunnel; "Five Highs": high ground stress, high seismic intensity, high ground temperature, high sea level, and high environmental requirements.

The total length of a plateau railway, which started construction in November 2020, is 1011km. The environment along the line is harsh, and the bridge tunnel ratio is as high as 95.8%. The construction period is as long as 10 years. A certain plateau tunnel has a total length of 42.3km and is designed as a double track separated single track railway tunnel with a maximum burial depth of 1506m. The project has the following characteristics: "One length": This tunnel is the longest tunnel in China's railway; "Two Duo": There are many natural disasters along the line and many unfavorable geological conditions in tunnels; "Four Difficulties": Difficulty in ventilation and dust reduction during long-distance excavation construction, difficulty in accurately predicting and protecting against high ground stress and rock bursts, difficulty in temperature reduction and prevention during long-distance excavation of high ground temperature tunnels, and difficulty in organizing construction with multiple working faces inside the tunnel; "Five Highs": high ground stress, high seismic intensity, high ground temperature, high sea level, and high environmental requirements.

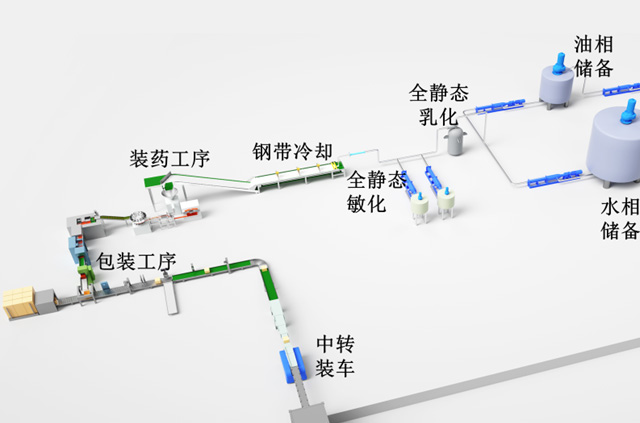

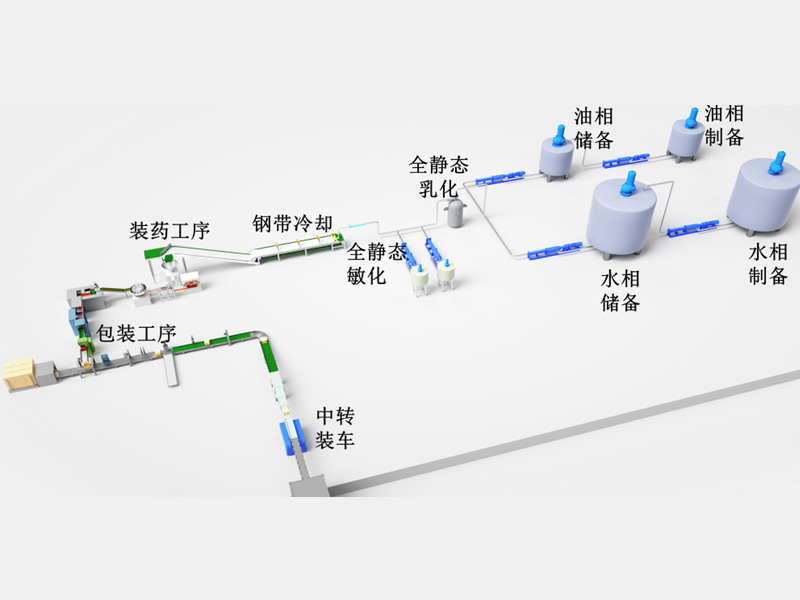

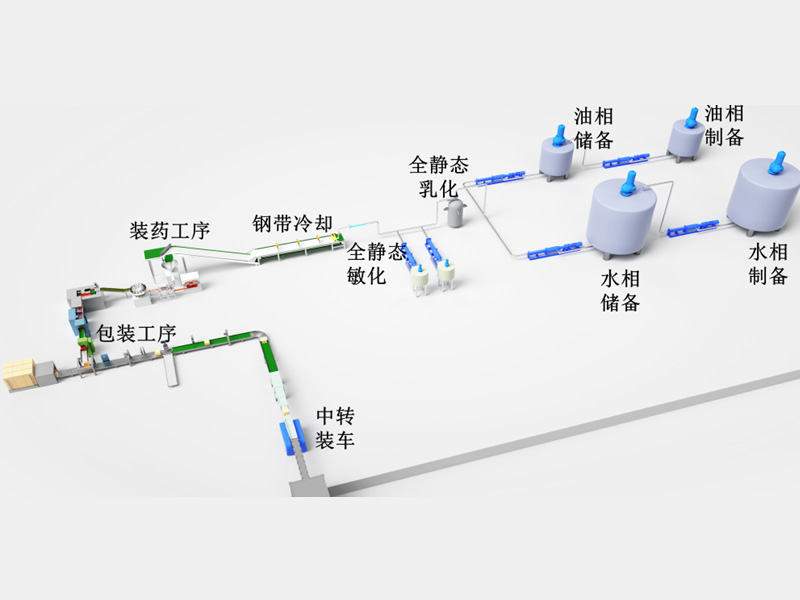

As a major technology provider, Hunan Jinshi Intelligent Manufacturing Technology Co., Ltd. is a high-tech enterprise specializing in the transfer of emulsion explosive production process technology, research on emulsion explosive fully static production lines, transportation vehicles, charging vehicles, wireless electronic detonators, and blasting technology. It is a holding subsidiary of Jinshi Resources Group, and the intelligent charging vehicle for the tunnel has the following key technologies:

(1) Clothing and medication system:High conveying accuracy of each component, and real-time adjustable ratio;

(2)Real time adjustment technology for charge density:Low density explosives can be loaded into peripheral holes, auxiliary holes, etc., while high-density explosives can be loaded into slot holes, bottom holes, etc., with a density of 0.7-1.3kg/L and an adjustable detonation speed of 3000-5000m/s;

(3)New energy lithium iron phosphate battery electric drive technology:No exhaust emissions during loading, green, environmentally friendly and efficient;

(4)Heavy load telescopic arm loading platform technology:The dressing medicine device can be directly placed close to the borehole, and the short distance delivery has low pressure efficiency and high flushing pipeline waste;

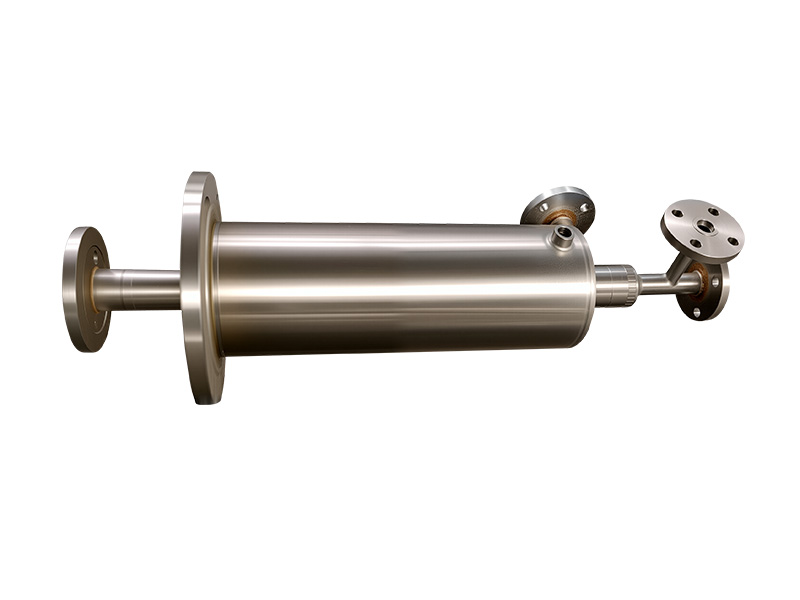

(5)Explosive technology for bulk emulsion explosives:Coupling charging through slotted holes, reinforced charging at the bottom of other holes+uncoupled charging, low-density charging through peripheral holes, can increase footage, control over excavation and reduce drilling. During the construction process of the plateau tunnel, the tunnel specific emulsion explosives developed by Jinshi Intelligent Manufacturing, which were loaded by the tunnel intelligent charging vehicle, can be reliably detonated, as shown in the following picture.

Intelligent Charging Vehicle for BCR-0.5-II Emulsion Explosive Tunnel at the Entrance of a Plateau Tunnel

Intelligent Charging Vehicle for BCR-0.5-II Emulsion Explosive Tunnel under Construction

The charging efficiency, blasting depth, and smooth blasting effect are all better than those of manual blasting

After using the tunnel intelligent charging vehicle, the labor quota was reduced from 12 people to 4 people. The charging efficiency went from waiting on the pier to the entire blasting process, which took about 2 hours. The high-density coupling charging of the cutting hole had a good blasting effect, and the blasting depth of the same depth hole was increased by 15% to 20% compared to manual operation. The low-density charging of the surrounding holes improved the light blasting effect. By optimizing the hole network parameters, the number of holes punched could be reduced by about 15% to 20%. The intelligent loading vehicle for tunnels reduces the labor quota, reduces the labor intensity of workers, improves comprehensive construction efficiency, reduces comprehensive construction costs, and reduces operational safety risks.

The successful application of BCR-0.5-II emulsion explosive tunnel intelligent charging vehicle in a certain plateau tunnel marks the realization of mechanized operation in tunnel charging and blasting! This is a major innovation and breakthrough in tunnel drilling and blasting construction technology in China, providing strong technical support for tunnel construction. Combined with the wireless electronic detonator technology currently being developed by Jinshi Intelligent Manufacturing, tunnel charging and blasting will develop towards unmanned and intelligent directions.

简体中文

简体中文

Online

Online