On January 22, 2025, the "KC type emulsion explosive full static emulsifier", "KC type emulsion explosive ground station full static emulsification formula technology and equipment", and "KC type emulsion explosive full static on-site mixing multi-purpose vehicle" jointly developed by Hunan Jinshi Intelligent Manufacturing Technology Co., Ltd. and Hubei Dongshen Chutian Chemical Co., Ltd. passed the scientific and technological achievement appraisal organized by the Ministry of Industry and Information Technology in Daye City, Hubei Province. The appraisal committee unanimously believes that the "KC type emulsion explosive static emulsifier" has reached the "international leading" level; The "KC type emulsion explosive ground station full static emulsification formula technology and equipment" and "KC type emulsion explosive full static on-site mixed multi-purpose vehicle" have reached the "international advanced" level.

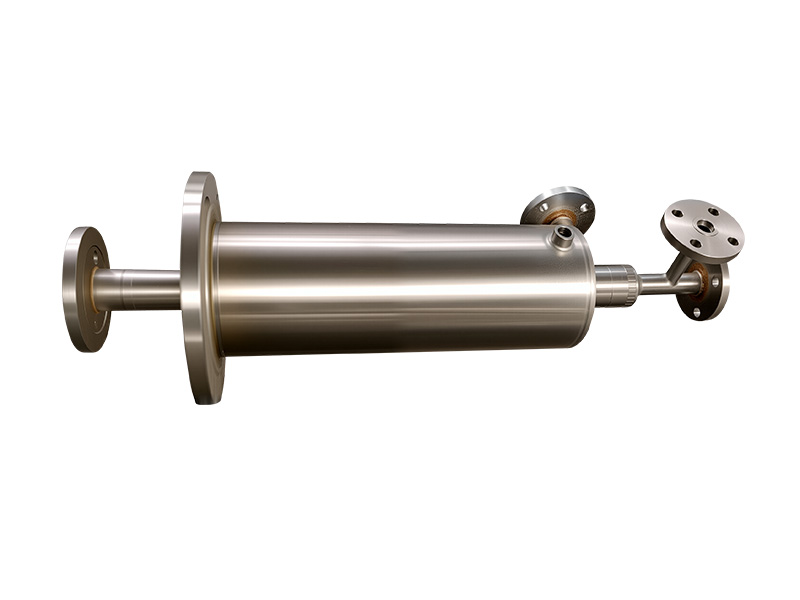

The "KC type emulsion explosive full static emulsifier" does not require mechanical stirring and directly forms emulsion through static spraying. It can form small droplets in a short time and form a stable emulsion matrix after passing through a special channel, achieving the integration of coarse emulsion, fine emulsion and emulsion, that is, one-time spraying into emulsion; The overall structure is simple and compact, forming a series of products that can be applied in production lines, ground stations, and vehicle systems, completely replacing the existing first level dynamic emulsifier or dynamic coarse emulsifier+static fine emulsifier in the emulsification process, and improving intrinsic safety production. The maximum production capacity reaches 45t/h, and the production capacity can be infinitely adjusted between 0.5-45t/h. It has good emulsification effect, wide adaptability to raw materials, and can adapt to all emulsion explosive formulas. Realize continuous full static emulsification, with a simple operation process and fast milk production speed. It can be stopped and started immediately without any material head or tail.

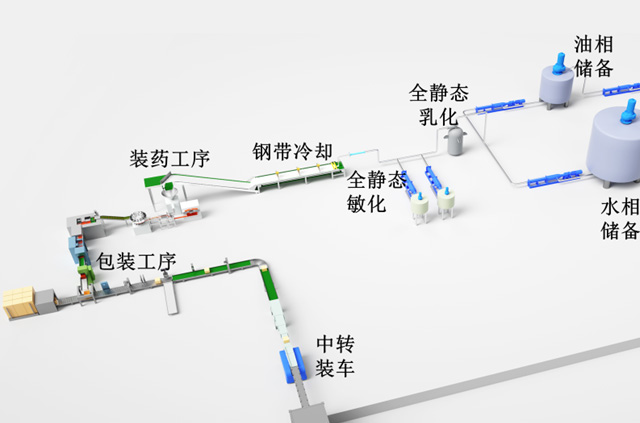

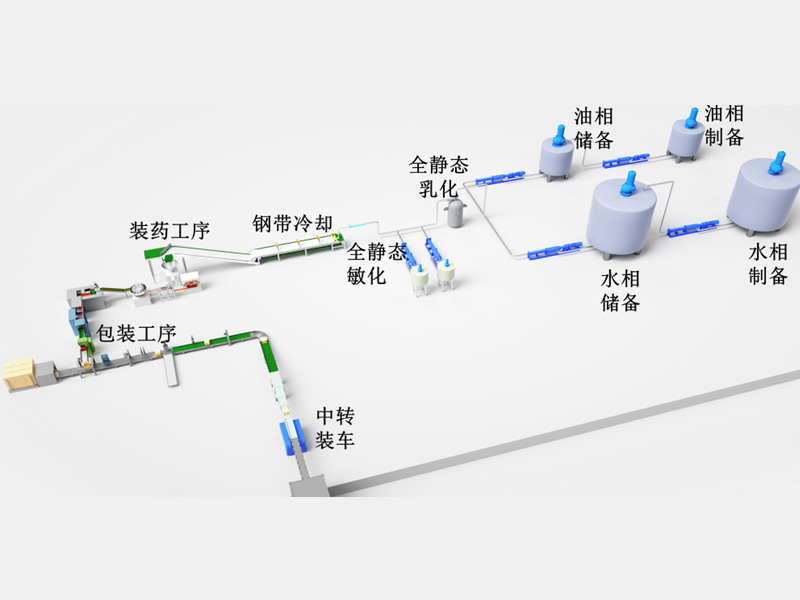

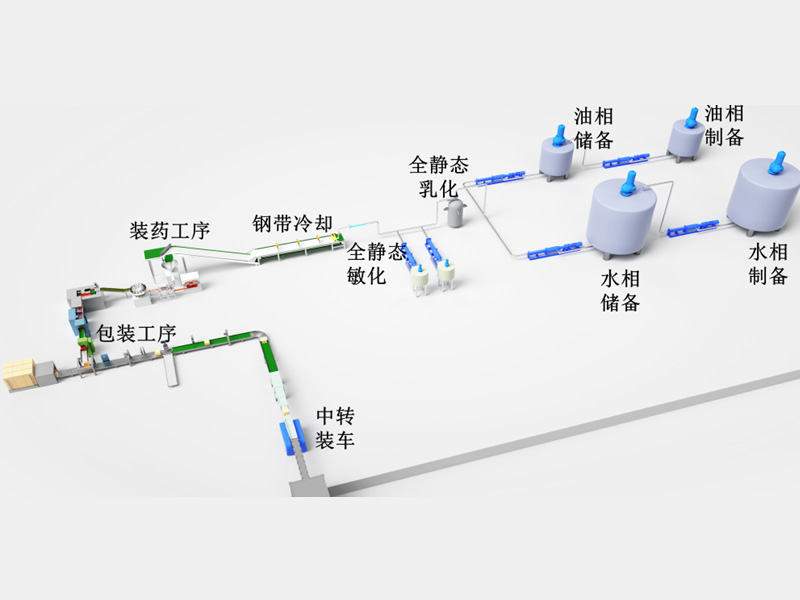

The "KC type emulsion explosive ground station" abandons traditional mechanical mixing and adopts static spraying to directly form emulsion, replacing the existing first stage dynamic emulsifier or dynamic coarse emulsifier+static fine emulsifier combination in the emulsification process. The entire line has no Class 0, Class I, or Class II equipment, further improving the intrinsic safety level. The maximum production capacity is 45 t/h, and there is no material head or tail during production. The product storage period exceeds 180 days, and various performance indicators exceed national and industry standards.

The "KC type emulsion explosive full static on-site mixing multi-purpose vehicle" innovatively realizes the integration of coarse milk, fine milk and sensitization, realizes unmanned production mode, can be started and stopped at any time, and has no material head or tail. The newly developed triple plunger pump delivers oil phase, water phase and sensitizer in proportion for static emulsification and sensitization, without the need for flow meters. The material ratio can be accurately conveyed through the triple plunger pump, and the whole vehicle has no Class 0, Class I, or Class II equipment, which is inherently safe and reliable. Adopting a new energy power system with no exhaust emissions, oil and water phase vehicles are equipped with air flow agitation, electromagnetic steam generators for heating and insulation, automatic vehicle control, unmanned production, and direct injection of explosive raw materials such as ammonium nitrate into the blast hole. Realize various functions such as on-site oil-water phase preparation, on-board milk production, and on-site mixing, with multiple uses including mixing vehicles, loading vehicles, ground stations, matrix distribution vehicles, and on-site distribution vehicles for bulk explosives.

The above projects have obtained 2 authorized invention patents, 12 utility model patents, and published 2 SCI papers.

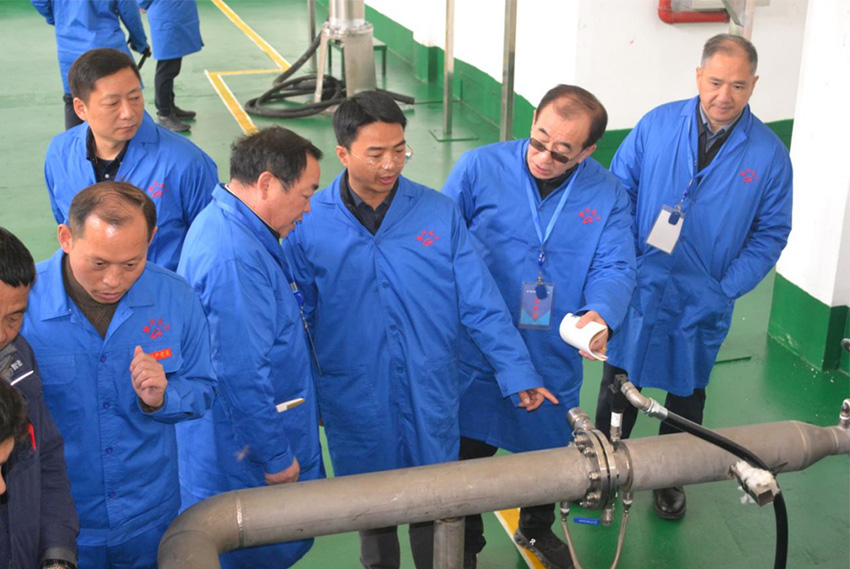

The meeting was chaired by Xiao Yuehua, the second level inspector of the Safety Production Department of the Ministry of Industry and Information Technology, and attended by leaders from the Hubei Provincial Office of National Defense Science and Technology, Huangshi Municipal Bureau of Economy and Information Technology, and Daye Municipal Bureau of Economy and Information Technology. Chairman Zhang Youqian of Hubei Dongshen Chutian Chemical Co., Ltd. and General Manager Tang Xiuyong of Hunan Jinshi Intelligent Manufacturing Technology Co., Ltd. attended the appraisal meeting. The appraisal committee is composed of seven highly influential national level senior expert members in the civil explosive industry.

The three projects identified have been fully recognized by the attending leaders and experts, which is not only a powerful witness to the innovation strength of Hunan Jinshi Intelligent Manufacturing Technology Co., Ltd. and Hubei Dongshen Chutian Chemical Co., Ltd., but also a high praise for the two companies' deep cultivation in the field of technology. From the perspective of industry development, the project results accurately align with the policy orientation of the civil explosive industry, injecting new vitality into the industry and promoting the transformation of production modes towards intrinsic safety, intelligence, and green; At the technical level, the project has broken through multiple key technologies, filled industry gaps, driven the coordinated development of upstream and downstream industrial chains, comprehensively promoted technological innovation in China's civil explosive industry, and helped the industry embark on a new journey of high-quality development.

Hunan Jinshi Intelligent Manufacturing Technology Co., Ltd

Tan Weiqi

2025.1

简体中文

简体中文

Online

Online